Process For Preventing Honeycomb Core From Collapsing - Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Then vertically placing the shaped honeycomb. The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb. Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being.

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. Then vertically placing the shaped honeycomb. To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures.

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. Then vertically placing the shaped honeycomb. Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures.

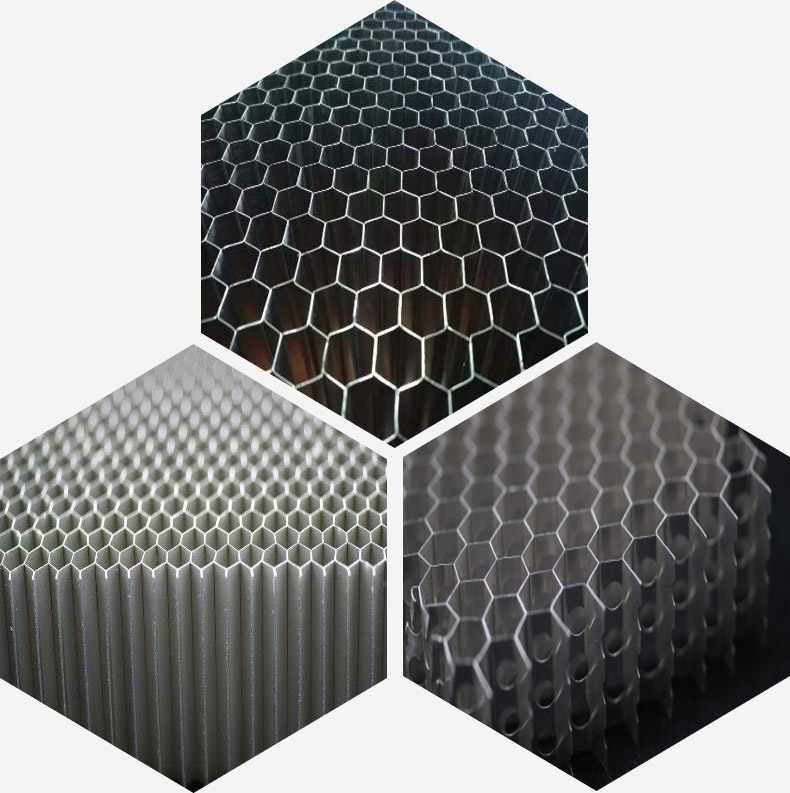

Core Argosy International

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Then vertically placing the shaped honeycomb. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb..

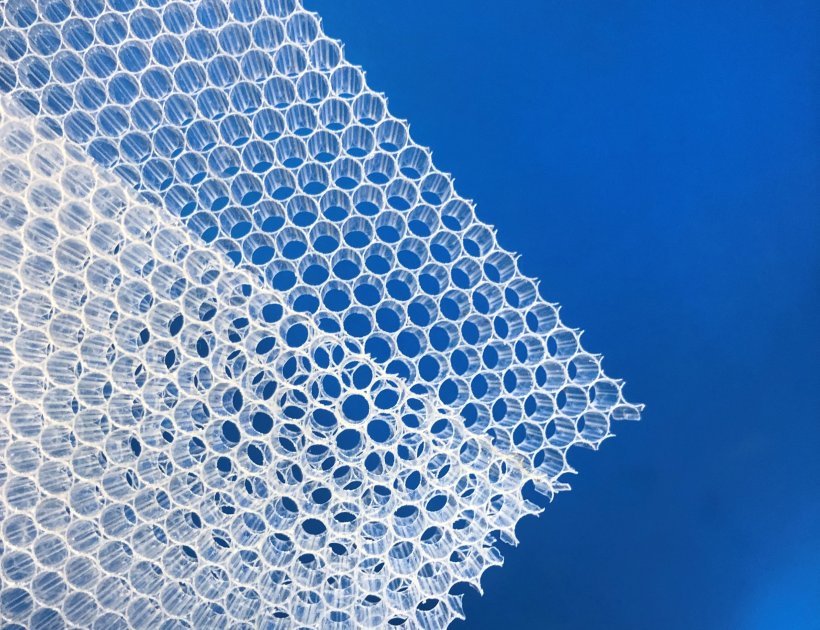

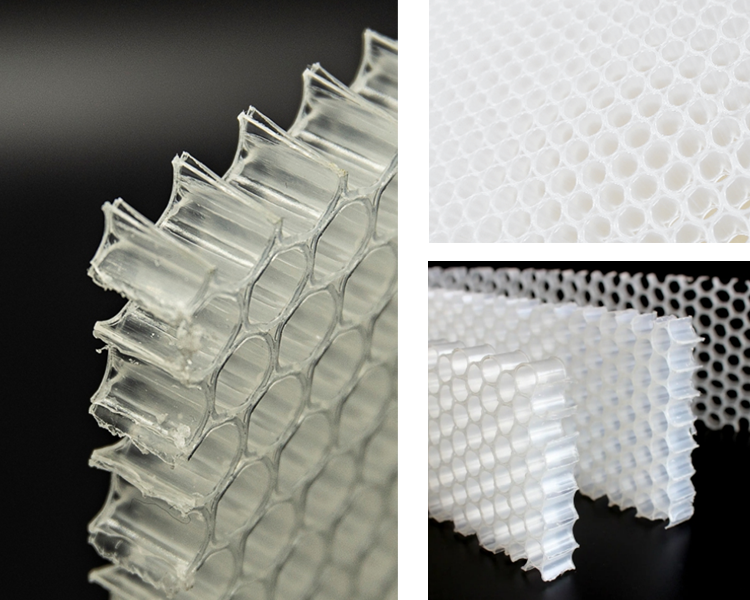

PP panel_PC core

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb..

China Over Expanded Core Manufacturers Suppliers Factory

The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb. Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To safely apply edge banding to honeycomb core panels,.

China Flexible Core Manufacturers Suppliers Factory

Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Then vertically placing the shaped honeycomb. To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. Core crush is a manufacturing defect occurred.

PC flow straightener

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. The invention belongs to manufacture technology of composite material field, it is related.

Geometry for core. (a) core. (b) core

To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Core crush is.

Kerr Panel

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. Core crush is a.

Kerr Panel

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Then vertically placing the shaped honeycomb. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To address adhesive failure and premature collapse in traditional aluminium honeycomb, this study presents a novel. To safely apply edge.

Core,Products,SuiJin Co., Ltd.

Firstly, shaping a honeycomb, and shaping the honeycomb by using a honeycomb shaping die; To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. Then vertically placing the shaped honeycomb. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures..

Aramid Core TOPOLO New Materials

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. To address adhesive.

To Address Adhesive Failure And Premature Collapse In Traditional Aluminium Honeycomb, This Study Presents A Novel.

Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. To safely apply edge banding to honeycomb core panels, a solid edge reinforcement material is required to prevent the core material from being. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures. Core crush is a manufacturing defect occurred during the autoclave curing process of composite honeycomb sandwich structures.

Firstly, Shaping A Honeycomb, And Shaping The Honeycomb By Using A Honeycomb Shaping Die;

The invention belongs to manufacture technology of composite material field, it is related to the technical method for preventing honeycomb. Then vertically placing the shaped honeycomb.